CAD and 3D Design

We offer comprehensive metal engineering services, from design to fabrication, ensuring precision and quality at every step.

CAD and 3D

APSM Engineering uses industry-leading software to deliver an efficient, accurate, and fully transparent design-to-manufacture solution for our customers.

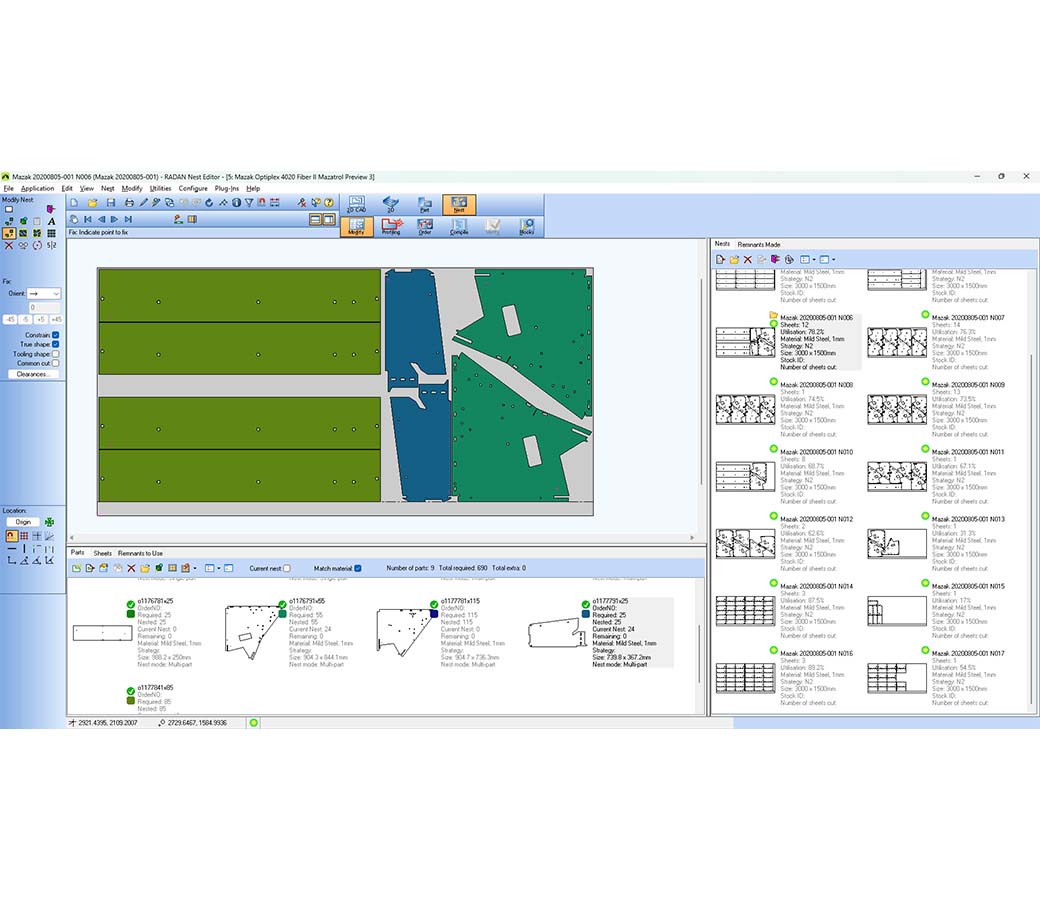

For quoting and production planning, we use Hexagon RADAN and E2i software to quickly and accurately assess customer parts. These systems allow us to import customer drawings and files, apply real-world material and cutting data, and create highly efficient nests. By optimising material usage and cutting time at the quotation stage, we can provide fast, competitive, and reliable pricing, while ensuring production efficiency from the outset.

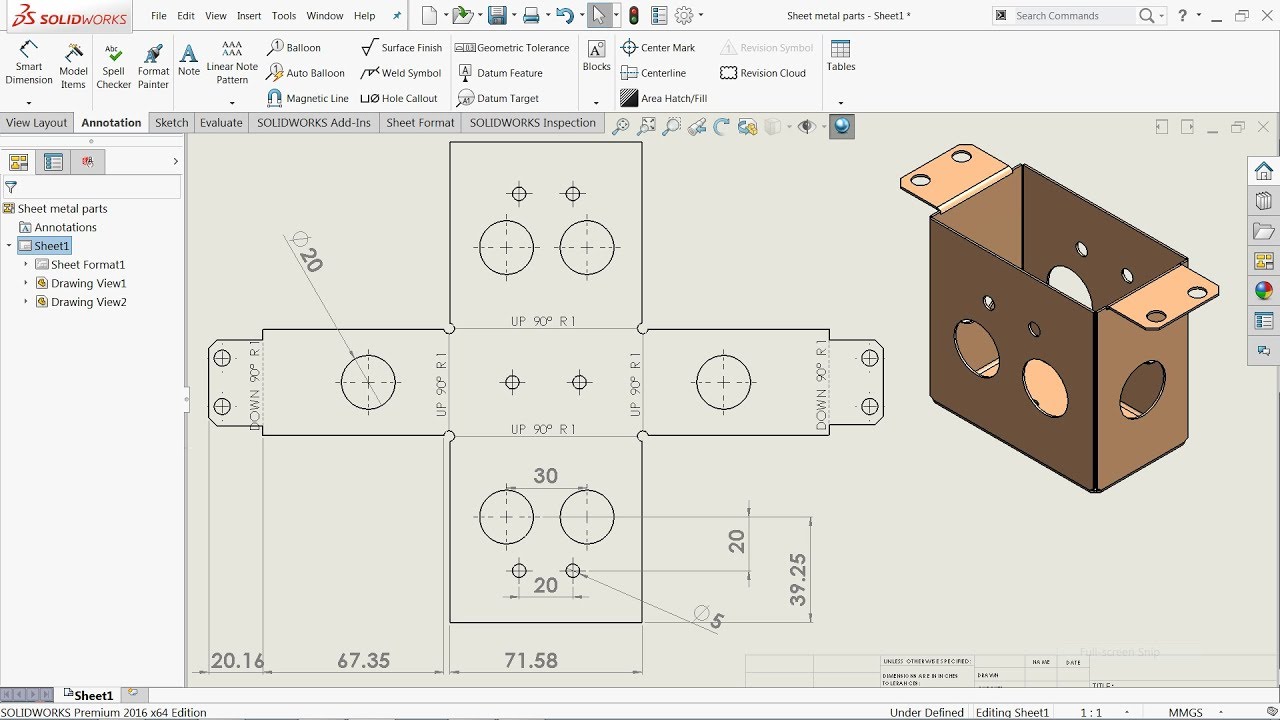

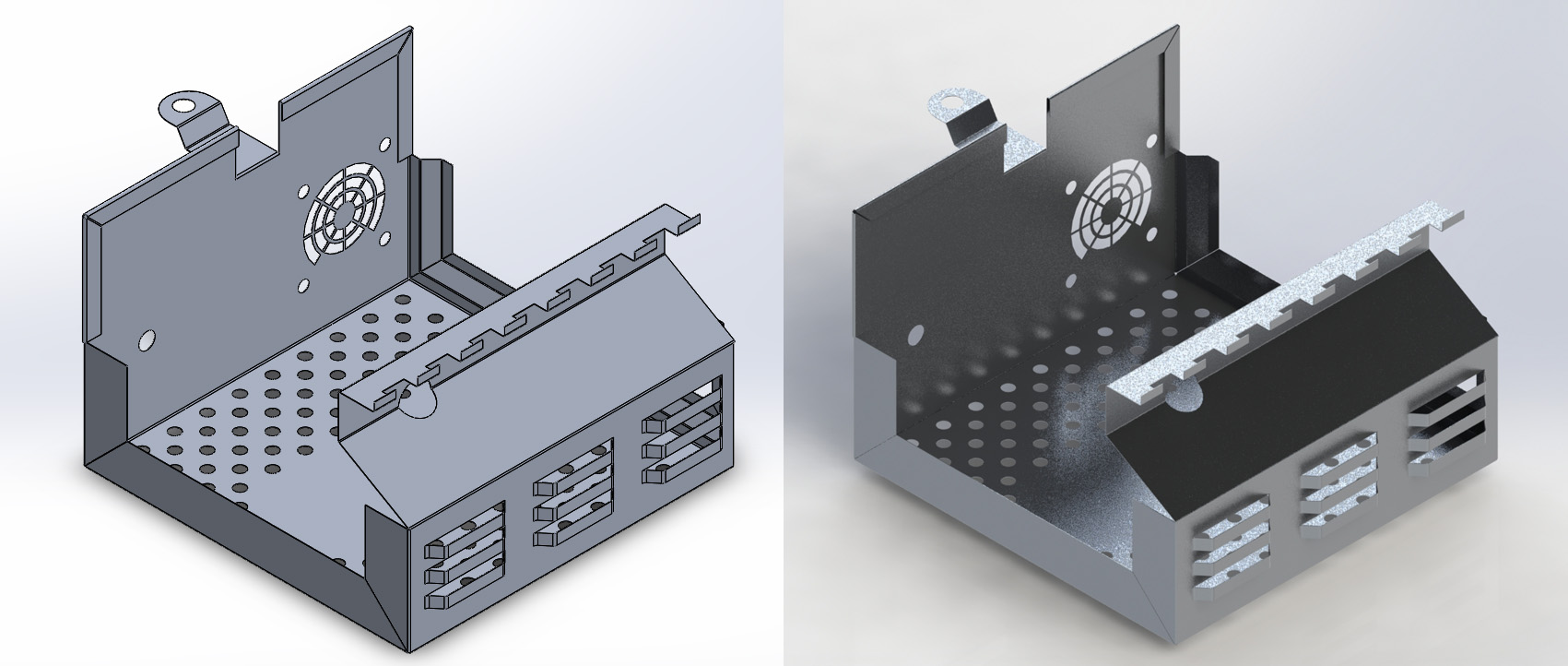

For design and development, APSM uses SolidWorks to generate detailed 3D models, assemblies, and manufacturing drawings. This enables us to work closely with customers to refine designs, resolve potential issues before production, and ensure components are optimised for laser cutting, folding, and fabrication. Using SolidWorks, we can also produce high-quality rendered images of parts and assemblies, giving customers a clear visual representation of the finished product before manufacture begins.

By combining advanced quoting and nesting software with professional 3D design and rendering tools, APSM Engineering offers a complete design, manufacture, and cost solution. This integrated approach reduces lead times, improves accuracy, minimises material waste, and gives customers confidence that their parts are fully engineered, cost-effective, and ready for production.

Radan

Radnest is a high performance true shape nester for punching and profiling machines supplementing the nesting utilities present in a standard RADAN system, allowing the user to have full control over part placement and nest generation either manually, semi-automatically or fully automatically. Radnest can dramatically increase sheet utilisation and significantly reduce the time taken to create nests.

Radnest allows 2D profiles to be imported on mass setting attributes such as material, thickness and quantity to be set as part of the quick and easy process, files can be cleaned and healed on import removing drawing borders, text and dimensions whilst closing small gaps and removing rogue geometry, preferences can be saved into templates allowing you to tailor your import to your customers data.

Kits can be created within RADAN helping avoid parts being missed from assembly lists, enter into Radnest which kit you would like to manufacture and how many, Radnest will then explode the kit into its component parts with the correct materials, thicknesses and quantities.

Profiling with Radnest

When used with Radprofile, Radnest can automatically produce common line cuts between adjacent parts to further increase material utilisation and reduce cycle time, gaps between components are controlled by the kerf width created by a given material, thickness and cutting method for a specific machine, this data is stored within RADAN meaning that complete automation is possible. Radnest is able to mix different nesting techniques on the same sheet whether that means Rigid Kits, Picking Clusters, Common Cutting or Standard Spaced, the result is industry leading results for today’s modern machinery and manufacturing techniques.

E2i

Features at a glance:

- Unique links to RADAN CAD/CAM

- Advanced functionality for nesting operations

- User level security

- Simplified stores module

- Capacity planning

- Flexible stock control

- Accounting links

- Assembly and BOM management

- All records easily retrievable

Solidworks

What is SOLIDWORKS Design?

SOLIDWORKS® Design is the 3D CAD solution of choice for professionals worldwide who need to take design innovation further, produce products faster, and reach the highest levels of efficiency in their day-to-day product development work. Decades of user-driven enhancements and a relentless R&D focus on user experience have made SOLIDWORKS Design not just powerful, but also easy to learn and fun to use.

- Trusted industry standard solution

- Powerful and proven 3D modeling capabilities

- Production-ready documentation and 2D drawing solutions

- Generative and assistive AI-powered features for drawings and assembly designs

- Intuitive user interface designed by engineers, for engineers to use

- Cloud Services real-time collaboration tools for sharing and marking up designs

- Secure, CAD-aware cloud file and revision management

- Out-of-the-box ideation to manufacturing workflows

- Integrated simulation, rendering, and CAM tools

SEE SOLIDWORK IN ACTION – Video